Enjoy Access to the Latest Polystyrene Slab Solutions in South Africa

Light Weight, Fast and Affordable

It can be tough deciding on which Polystyrene Slab solutions to employ, with so many service providers vying for your business. However, it doesn’t need to be. Simply demand the best, and don’t settle for anything less. Our fast floor system is lightweight, superior and economical. These concrete polystyrene slabs continue to set the standard for excellence.

Thanks to our advanced polystyrene slab solutions, we continue to innovate and advance the polystyrene insulated rib and block slab industry. In fact, we continue to set the standards for excellence in the industry and work with our vast range of clientele to not only meet but also far exceed their expectations.

Our polystyrene slab engineering professionals have mastered this art, and we continue to deliver the highly sought after polystyrene insulated rib and block slabs to our valued clients. They’re specifically designed for long-distance building projects, where lighter weights are required on load-bearing walls. The polystyrene system has superior insulation and is eco-friendly and in with line with modern green building requirements and techniques.

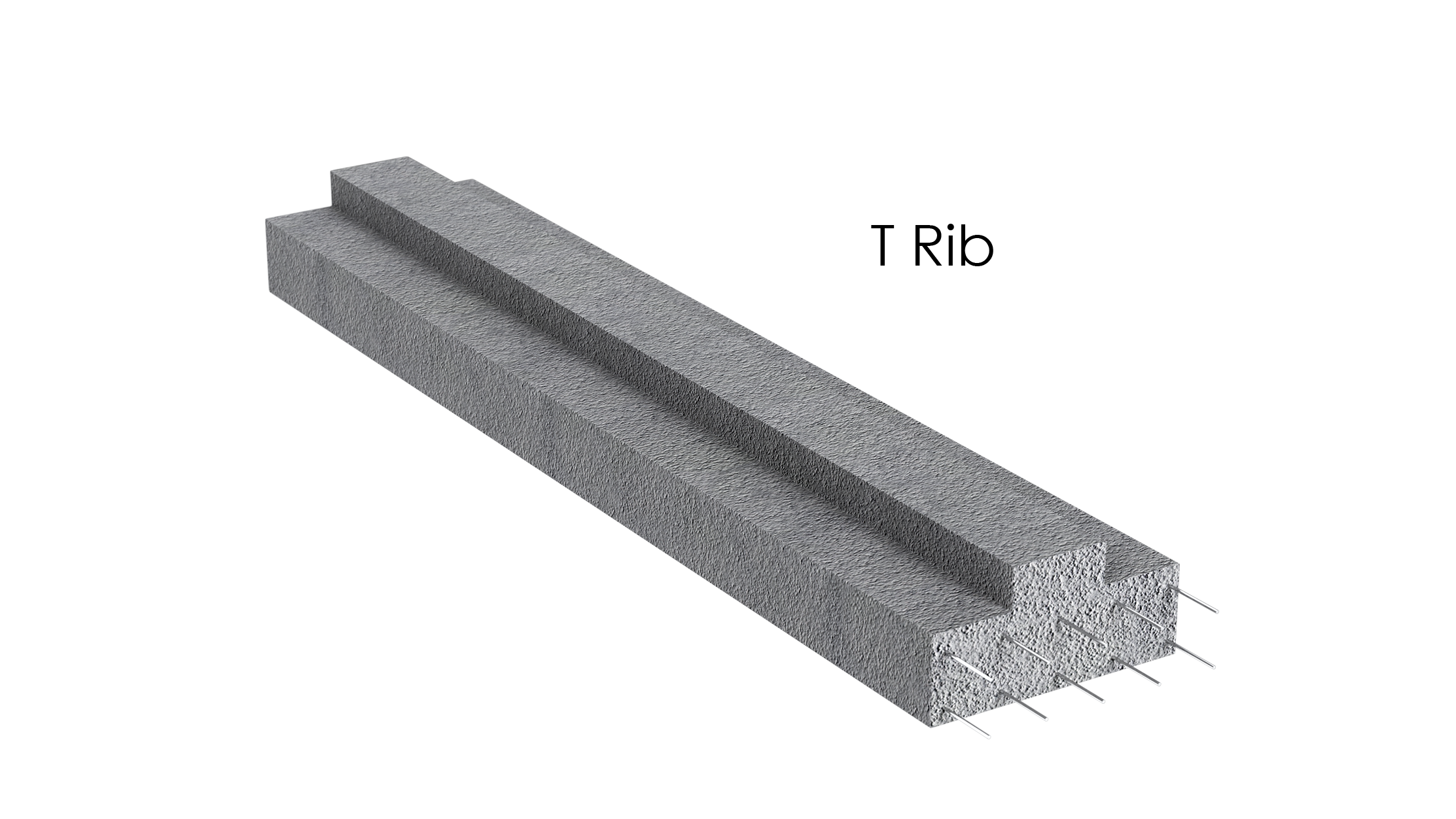

Slab Rib / Lintel

T-shaped design for strength over long spans. Propless on short spans under our supervision only.

3d Slab Installation GuideThis lintel is designed for high performance, intended to withstand stressful loads which most other lintels cannot handle. ( View our Typical Slab Layout ) Click here

This has been tested and certified for strength, precision, and efficiency. ( See the UJ University test report ) Click here

Props are moved further back under our engineer’s supervision, resulting in fewer props which significantly reduces installation time and costs. ( Interested in more of our Technical documents? ) Click here to view more

A further 5% concrete saving is achieved as a result of the unique T-Shape spans over 5m are straight and perpendicular for hassle-free propping.

Width 150mm

height 60mm

Wire Strands 5/7/8 or 10

Weight 21Kg/m

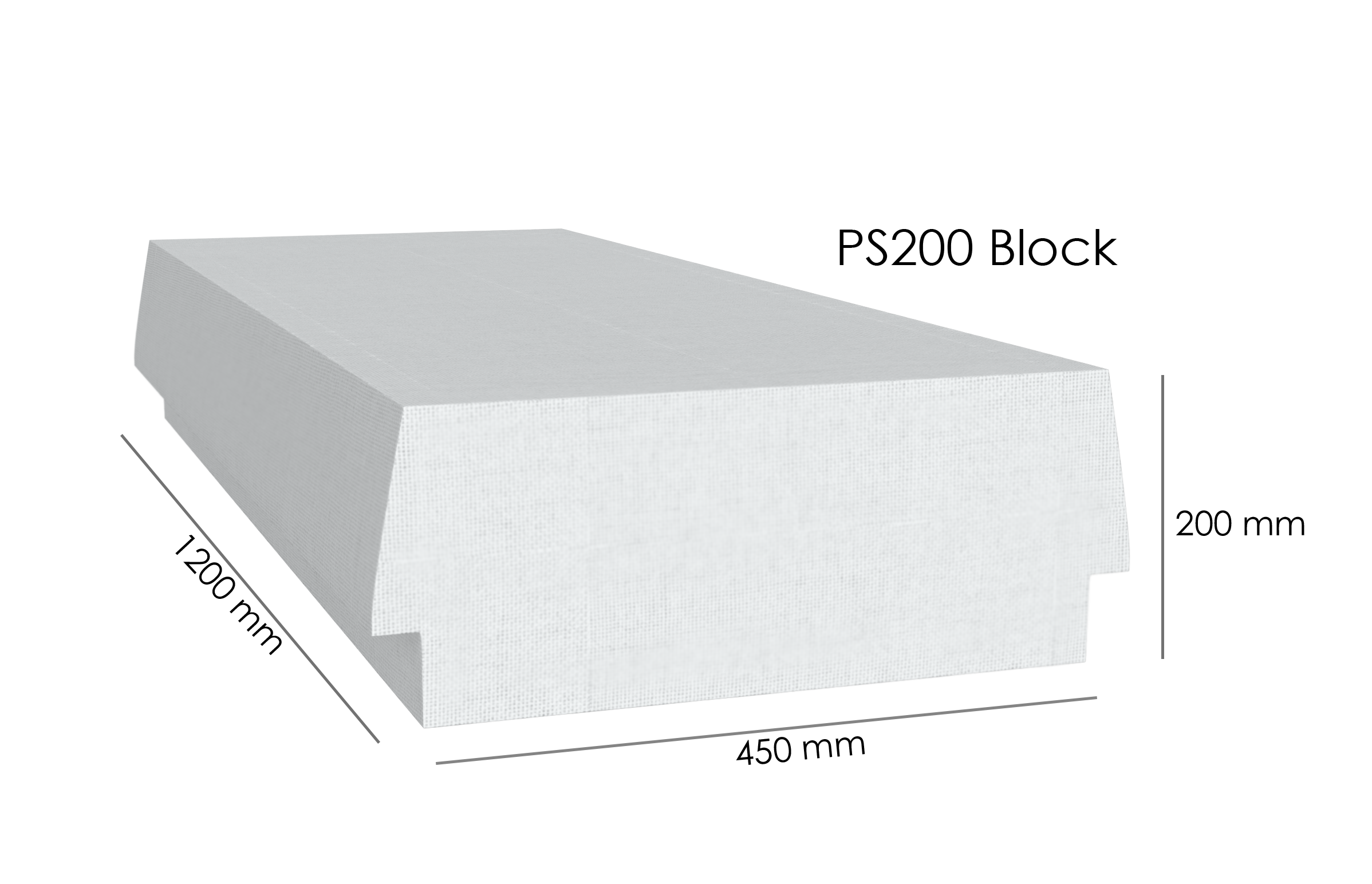

Polystyrene Block

The Polystyrene Blocks replaces the concrete block as a void filler resulting in many advantages, such as:- – Lightweight for faster and easier installation.

- – Semi propless for easier and quicker installation.

- – Lightweight for less loads on the structure walls and foundations.

- – Sound and thermal insulation properties add to the environmental benefits.

- – Reduced Delivery costs for long distance hauls.

PS200 450mm x 1200mm x 200mm 255mm Slab PS150 450mm x 1200mm x 150mm 200mm Slab PS280 450mm x 1200mm x 280mm 340mm Slab

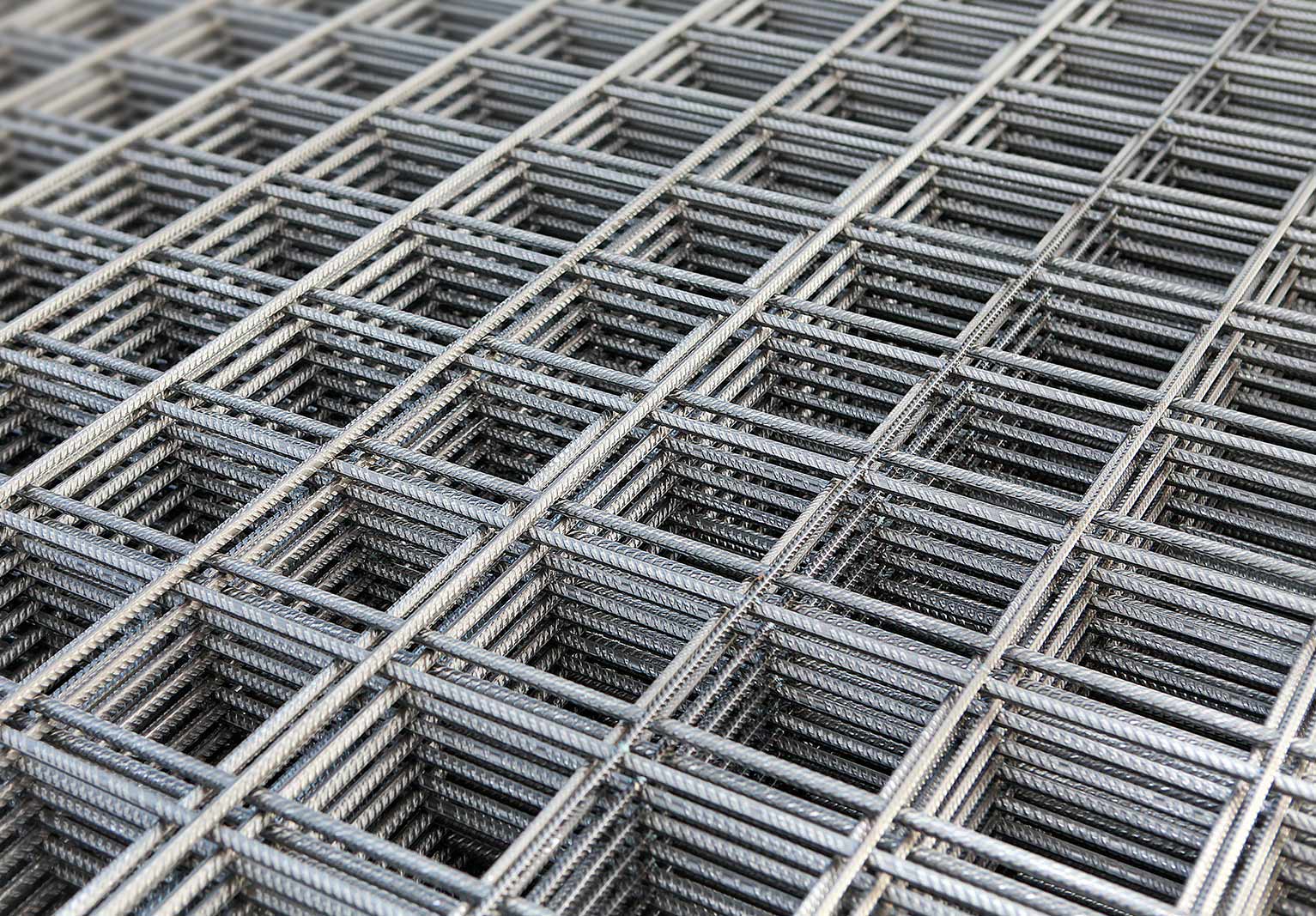

Ref.100 Mesh

Anti-crack weldmesh supplied as part of the package or as required.

The anti-crack weld mesh provides durability to the structure by minimising surface cracks when exposed to the elements.

Y10 or Y12 Rebar

Stiffener steel supplied as part of the package or as required.

Ribs are propped at regular 1.5m intervals and under every block.

Reinforcing bars are inserted above to form stiffener rib when enhances slab stability.

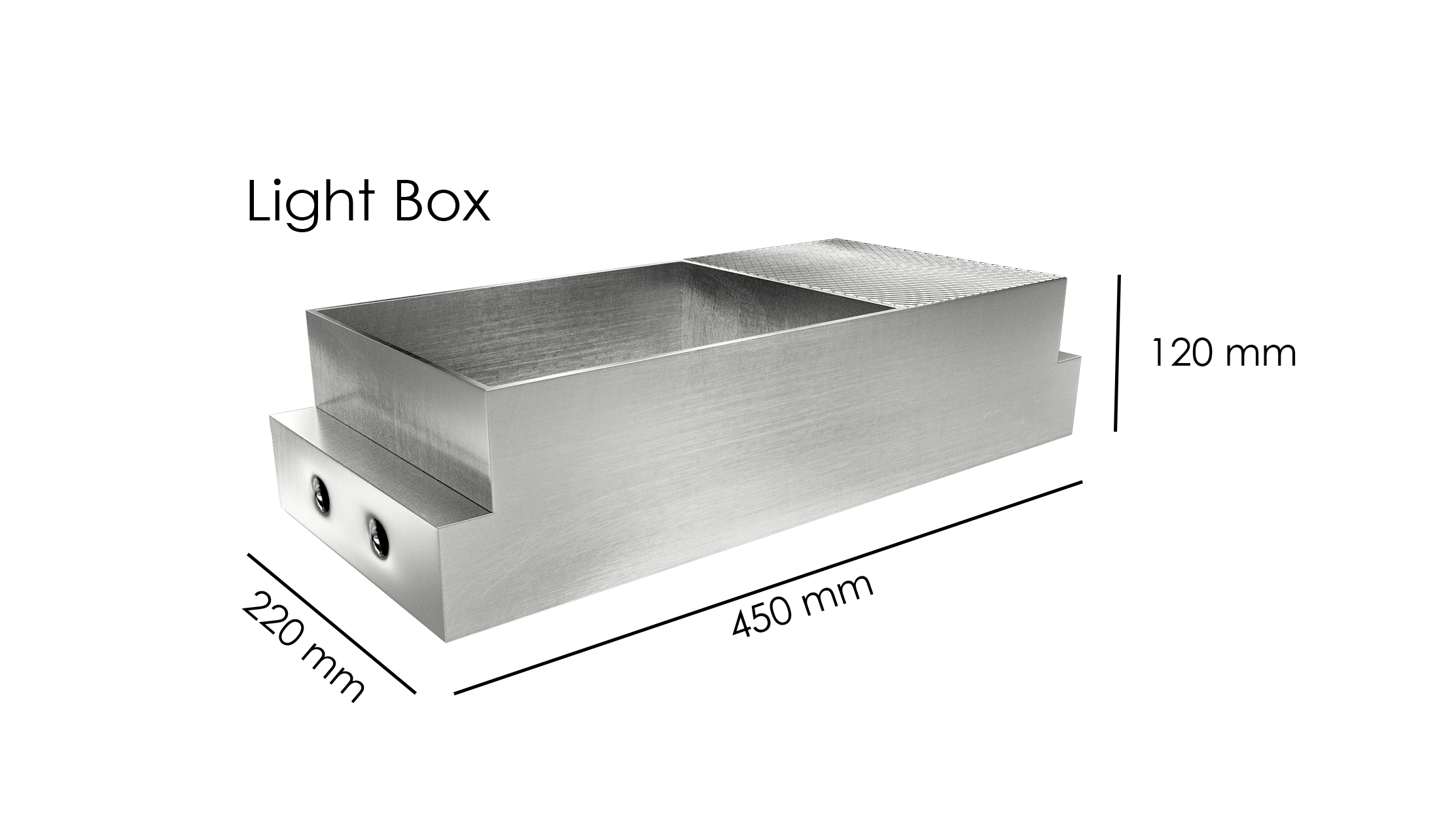

Lightboxes

Used by electricians for downlights.

Size : 450 mm width

With a 75mm hole cutout plate

In-situ Concrete (ready mix)

A 60mm layer of 25mpA ready mix concrete is thrown above after our engineer’s inspection

Contact 0836395786 for ready mix quote (JHB only)

Props are kept in place for 21 days

A Complete Solution

Royal Concrete has been involved in creating masterpieces for over 30 years

We provide a complimentary Engineering service alongside the material supply including inspections and certifications.

Polystyrene Slab Benefits

- Sound Insulation – noise reduction

- Heat Insulation – keeping rooms cool in summer and warm in winter

- Fast Installation – Polystyrene blocks are light and less labour intensive due to this fact

- Lightweight and Economical – Easy and cheaper transport

- Light on Walls and Foundations – 35% (60kg) lighter per m2 than normal rib and block slabs

- Versatility and flexability in design

- Spans up to 8m are easily achieved

- Less props required: Semi Propless up to 2m under our supervision

- Quick and easy installation for multi storey buildings

- Less load on the foundations and load bearing walls (up to 130Kg lighter per m2)

- Ceiling boards beneath the soffit required instead of plastering the soffit

- Factory produced – offering the highest quality crisp white polystyrene

- Our polystyrene is made with fire resistant material. This is manufactured by our sister company

- T Lintels are machine extruded and not made in moulds like our competitors’ products. Therefore the underside of our Lintel is rough, which serves as a good plaster adhesive surface.

- 40MPA concrete ribs is our standard as opposed to the 25MPA industry standards

- All trays are made from quality aggregates with minimum breakages

- Our polystyrene blocks are higher, resulting in less concrete consumed when compared to competitors.

- Hospitals

- Schools

- Residential/ Domestic

- Town Houses

- Retail

- Car Parks

- Office Buildings

Johannesburg, Soweto, Midrand, East Rand, Krugersdorp, Secunda, Fochville, Carletonville, Bloemfontein, Newcastle, Qwa Qwa, Pretoria, Mafikeng, Vereeniging, Vanderbijl, Vaal, Parys, Middelburg, Witbank, Mokopane, Polokwane and Towns within 400km radius.

Neighbouring Countries: Lesotho, Botswana, Swaziland, Namibia, and Zimbabwe.

View our Technical Slab Engineering Tables – Click Here