What is a rib and block slab?

What are different types of concrete slabs in South Africa?

June 4, 2020

What is a polystyrene concrete slab?

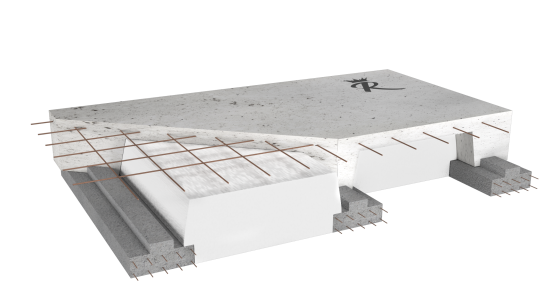

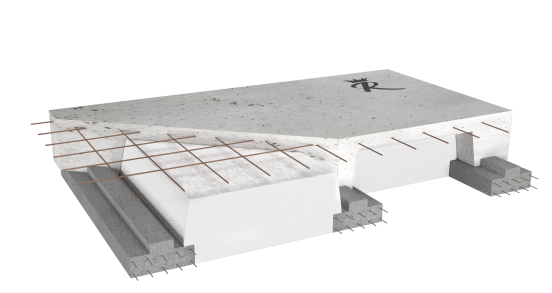

August 5, 2020Rib and Block Slabs are the most common slab system in South Africa. It is easily understood by 90% of builders, architects and engineers and is cost effective and easily installed. Temporary supports are kept in place for around 3 weeks while building above the slab can resume a few days after the slab is cast. Within this type of slab, systems are 2 types of blocks that can be used, polystyrene blocks or concrete blocks, lintels or ribs remain the same :

So , How does a rib and block slab work?

Click here to see rib and block installation video

Looking for more information on how much a concrete slab cost in South Africa?

Rib and block with concrete block: This is the standard type of slab, which can be plastered beneath. Its well understood and most common.

Other Benefits: Different designs are easily achieved as lintels and blocks are packed to the desired shape. Lintels are light compare to the hollow core and a few labourers can pack the slab within a few days. Minimal shuttering is required compared to in-situ type slabs. The slab is designed and delivered in some cases within a week whereas other slab types may take much longer.

Royal Concrete Slab advantages: Our lintels or ribs are unique and are T shaped (see below photo) and are much stronger and sturdy providing easy installation, minimal breakages, hassle free propping and level soffits. Our concrete blocks fit perfectly with the lintels resulting in easy plastering, the blocks are made from high quality material allowing for minimal breakages on site compared to competitors www.royalconcreteslabs.co.za

Some Drawbacks of rib and block slabs with a concrete block are: Its slightly more expensive than polystyrene rib and block slabs and weighs more so transport over long distances costs slightly more.

|

|

| Rib and Block with Concrete Block | Rib and Block with Polystyrene Block |

Rib and Block with polystyrene Block: This type uses the same concrete lintel or rib with a lightweight polystyrene block instead of a concrete block.

Benefits are: The cost of this slab is cheaper, and is lighter on foundations and walls (structure of the building) as well as cheaper transport costs over long distances. The lightweight blocks means the slab is installed easier and faster.

Royal Concrete Slab advantages: Our lintels or ribs are unique and are T shaped (see photo) and are much stronger and sturdy providing easy installation, minimal breakages, hassle free propping and level soffits. Our Polystyrene blocks are made from height density polystyrene compared to competitor products. Like we always advise, don’t settle for inferior quality polystyrene. Our higher depth blocks allow for less ready mix concrete to be used. Matched with our T lintels, this is an ideal rib a and block system designed for efficiency.

One drawback or polystyrene blocks: The polystyrene cannot be plastered easily and effectively, so it is advised that a ceiling board is used beneath. For many homeowners and builders, the use of ceiling boards to cover the slab is not an issue, as the modern look of dropped ceilings and canopies are preferred.

Click here to see more videos and concrete products or call the office 0118571003 or Whatsapp 0836395786 for a quote or advice.

Why Concrete Slab Construction is Best Left to the Professionals