What are different types of concrete slabs in South Africa?

How much does Rib and Block Slabs cost in South Africa?

June 2, 2020

What is a rib and block slab?

July 8, 2020Rib and block slab vs hollow core slab vs in-situ slab

Concrete slabs are referred to as the slab that is used in multi-story buildings. In a double-story home, this will be the concrete floor between the ground floor and the first floor. Some homes also have roof concrete slabs instead of tile roofs.

Generally, the concrete floor on the ground level is cast with ready-mix concrete by a contractor. The next level is where the engineer designs a slab to carry the floor above, and the builder purchases materials to install this concrete floor. Most companies that supply concrete slabs also provide engineering designs, inspections, and certifications.

There are a few slab systems that are common in South Africa:

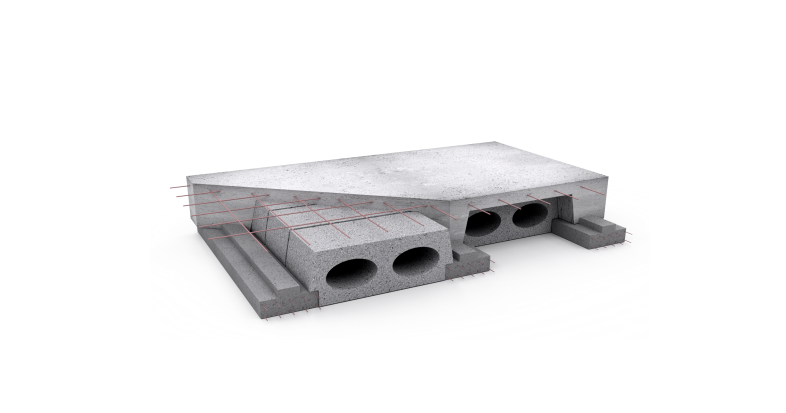

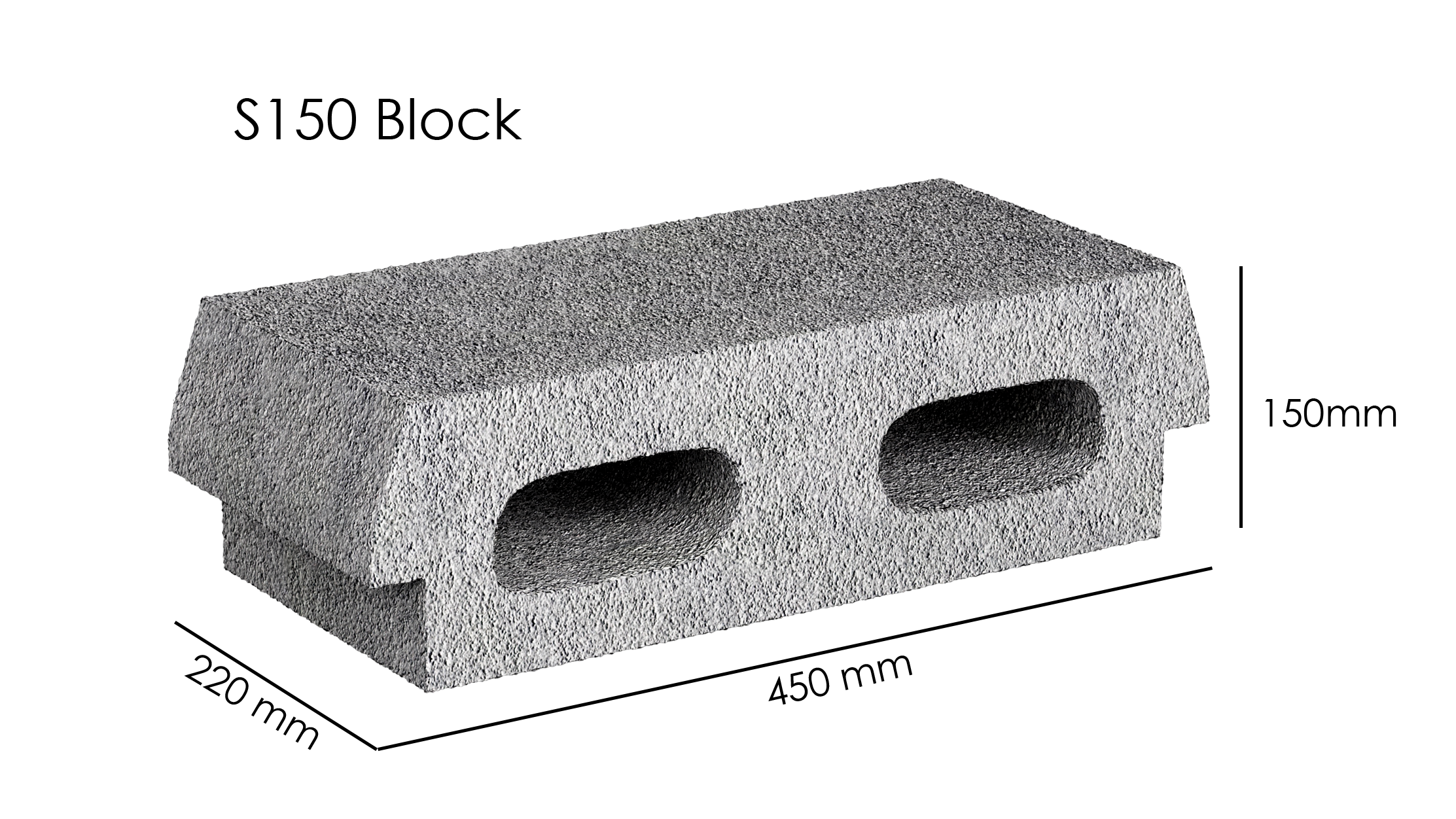

1. Rib and Block Slabs are the most common slab systems in South Africa. It is easily understood by 90% of builders, architects, and engineers and is cost-effective and easily installed. Temporary supports are kept in place for around 3 weeks while building above the slab can resume a few days after the slab is cast. Within this type of slab system are 2 types of blocks that can be used, polystyrene blocks or concrete blocks, and lintels or ribs remain the same:

Rib and block with concrete block: This is the standard type of slab, which can be plastered beneath. It’s well understood and most common. Drawbacks are: It’s slightly more expensive and weighs more so transport over long distances costs slightly more.

|

|

| Rib and Block with Concrete Block | Rib and Block with Polystyrene Block |

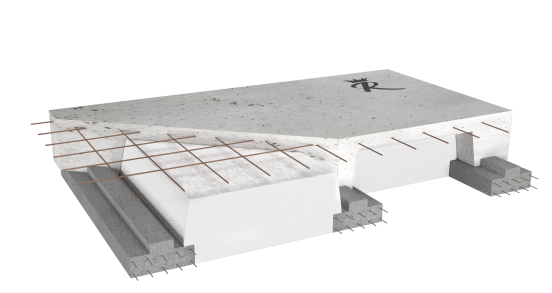

Rib and Block with polystyrene Block: This type uses the same concrete lintel or rib with a lightweight polystyrene block instead of a concrete block. The cost of this slab is cheaper and is lighter on foundations and walls (structure of the building) as well as cheaper transport costs over long distances. The lightweight blocks mean the slab is installed easier and faster.

There is a drawback: The polystyrene cannot be plastered easily and effectively, so it is advised that a ceiling board is used beneath. For many homeowners and builders, this is not an issue, as the modern look of dropped ceilings is encouraged.

2. In-situ slabs which are shuttered on-site by a contractor and use a lot of steel and concrete compared to the other 2 systems. Also costs more and is usually ideal for shopping centers tall buildings etc. Generally more dramatic curves and spans can be achieved, but at a higher cost. It is generally common practice in other countries where they build with columns and slabs instead of brickwork as load bearing.

|

|

| In-Situ Slab | Hollow Core Slab |

3. Hollow Core Slabs are precast in a factory in 1m wide section and length up to 10m. This type of slab is ideal for bigger townhouse projects where time is a factor. They are installed on-site with a crane and do not need temporary props.

Drawbacks on this slab type are: Crane costs and lead time make this slab cost more than the rib and block system. Builders are limited and can be held back to proceed with a project until the slab supplier delivers the slab and installs it themselves.